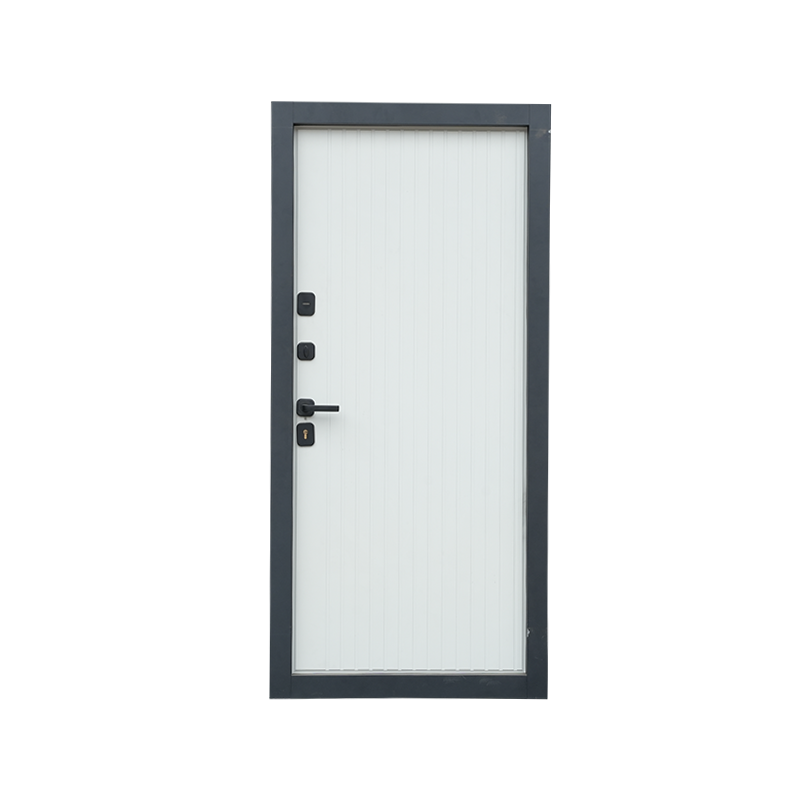

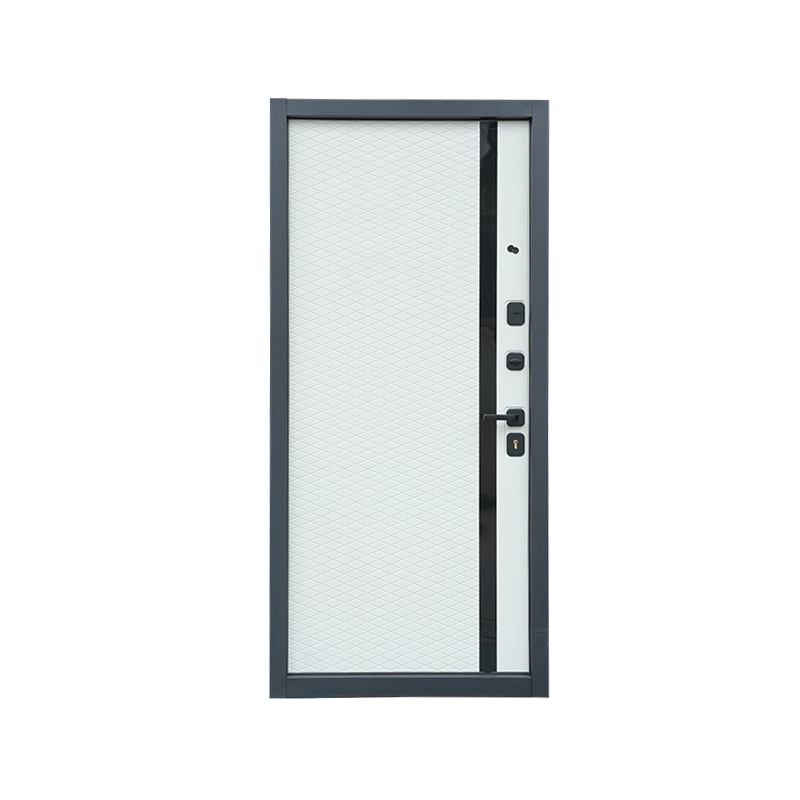

The Building Entrance Door stands as a pivotal interface between the external environment and the interior sanctuary. It faces relentless exposure: harsh weather, abrasive pollutants, constant human traffic, and the inevitable wear of daily operation. Beyond aesthetics and security, two critical attributes are increasingly defining the quality and long-term value of a superior Building Entrance Door: advanced self-cleaning or easy-clean surface technologies and exceptionally durable hardware systems. These features are not mere conveniences; they represent a fundamental commitment to longevity, reduced maintenance burdens, and sustained performance.

The Battle Against Grime: Self-Cleaning and Easy-Clean Surfaces

Maintaining the pristine appearance of a Building Entrance Door is a perpetual challenge. Dirt, grime, pollution residue, fingerprints, and water spots can quickly accumulate, diminishing the building's curb appeal and requiring frequent, costly cleaning. This is where innovative surface coatings, particularly high-performance fluoropolymer finishes, transform the equation.

The Science of Shedding Dirt: Premium fluoropolymer coatings (like PVDF - Polyvinylidene Fluoride) applied to metal Building Entrance Door surfaces (aluminum, steel) possess inherently low surface energy. This scientific characteristic means contaminants struggle to adhere strongly. Water, instead of forming droplets that leave mineral marks, tends to bead up and roll off the surface.

The "Lotus Effect" in Action: Much like the lotus leaf, these hydrophobic coatings encourage rainwater to form spherical droplets. As these droplets roll down the Building Entrance Door, they efficiently pick up and carry away loose dirt, dust, and other particulate matter. This natural rinsing action significantly reduces the adherence of grime.

Resisting Stains and Fading: Beyond easy cleaning, these coatings offer exceptional resistance to staining from common urban pollutants and harsh chemicals. They also provide superior UV stability, protecting the underlying metal and preserving the Building Entrance Door's color integrity for years, preventing the chalky fade often seen on inferior finishes. The door's appearance remains closer to its original state for far longer.

Practical Maintenance Benefits: The impact on facility management is tangible:

Reduced Cleaning Frequency: A Building Entrance Door with a high-quality self-cleaning coating requires far less frequent manual washing. Often, natural rainfall suffices for basic upkeep.

Simplified Cleaning Procedures: When cleaning is necessary, the process is easier. Stubborn dirt requires less aggressive scrubbing, reducing the risk of damaging the finish. Gentle detergents and water are often adequate.

Lower Lifetime Costs: Reduced labor hours for cleaning and less need for specialized cleaning chemicals translate directly into lower operational expenses over the lifespan of the Building Entrance Door.

The Unseen Engine: Durable Hardware Systems

While the surface faces the elements, the hardware – hinges (pivots or continuous), locksets, handles/pulls, closers, and associated mechanisms – bears the constant physical load of operation. The durability of this hardware is paramount for the smooth, safe, and reliable function of the Building Entrance Door year after year.

Material Matters – Stainless Steel & Zinc Alloy: Premium Building Entrance Door hardware relies on robust materials engineered for endurance:

Stainless Steel (Grades 304 & 316): The gold standard for corrosion resistance, especially in coastal or high-pollution areas (Grade 316 offers enhanced protection). Stainless steel hardware withstands moisture, de-icing salts, and atmospheric pollutants without rusting or pitting. It provides inherent strength for high-traffic doors and resists surface wear.

High-Quality Zinc Alloy (Zamak): When precision casting and robust surface finishes (like PVD - Physical Vapor Deposition) are applied, zinc alloys offer excellent corrosion resistance and mechanical strength at a potentially lower cost point than solid stainless. Modern PVD finishes can provide exceptional hardness and color stability.

Engineering for Load and Wear: Durable hardware isn't just about the base material:

Heavy-Duty Bearings: Pivots and hinges designed for Building Entrance Doors incorporate sealed or lubricated-for-life bearings to handle significant weight and frequent cycles smoothly, minimizing friction and wear.

Reinforced Mechanisms: Lock bodies and latch mechanisms are constructed with hardened internal components to resist forced entry attempts and endure repeated engagement and disengagement without failure.

Abrasion Resistance: Handles and pulls feature finishes and construction designed to resist the constant friction of hands, preventing premature wear and maintaining appearance.

Consequences of Hardware Failure: Compromised hardware on a Building Entrance Door leads to significant problems:

Operational Failure: A seized hinge, failing closer, or malfunctioning lock renders the door difficult or impossible to use properly, impacting accessibility and security.

Safety Hazards: A door that doesn't close properly, slams unexpectedly, or has a failing closer poses risks to users.

Increased Repair Costs: Replacing failed hardware is disruptive and costly, especially if it requires specialized labor or affects the door leaf itself. Premature hardware failure drastically shortens the effective service life of the entire Building Entrance Door assembly.

Aesthetic Degradation: Rusting, pitted, or worn hardware detracts significantly from the door's appearance and the building's image.

The Synergy: Surface and Hardware Working in Concert

The true value of a well-designed Building Entrance Door lies in the synergy between its easy-maintenance surface and its durable hardware:

Preserving Integrity: A self-cleaning finish protects the door's substrate from corrosive elements that could eventually compromise structural integrity near hardware mounting points. Conversely, durable, corrosion-resistant hardware prevents unsightly rust streaks from degrading the clean surface below.

Ensuring Long-Term Performance: Durable hardware guarantees the Building Entrance Door operates smoothly and securely for its entire lifespan. An easy-clean surface ensures that lifespan isn't cut short by aesthetic degradation requiring premature replacement. Both contribute directly to the door's functional longevity.

Reducing Total Cost of Ownership: This combination is a powerful driver for lowering lifetime costs:

Minimized Maintenance: Less frequent and less intensive cleaning saves labor and materials costs.

Avoided Repairs: Durable hardware drastically reduces the likelihood of mid-life failures and the associated repair expenses and downtime.

Extended Replacement Cycle: A Building Entrance Door that looks good and functions flawlessly for decades delays the substantial capital expenditure of a full door replacement.

Sustaining Curb Appeal and Function: A Building Entrance Door that remains clean and operates smoothly maintains the building's professional image and provides a positive, hassle-free experience for everyone entering or exiting. The entrance continues to function as intended – a secure, welcoming, and efficient portal.

Beyond Specification: A Mark of Quality Investment

Choosing a Building Entrance Door specified with genuine fluoropolymer coatings (or equivalent advanced finishes) and hardware constructed from high-grade stainless steel or premium finished zinc alloy is an investment in resilience. It signals an understanding that the entrance is a high-impact zone demanding materials and technologies engineered for real-world performance. Manufacturers offering these features typically adhere to higher standards in overall construction, fabrication tolerances, and testing protocols. The presence of these specific attributes often correlates with a superior overall product.

The modern Building Entrance Door is a sophisticated assembly where every component plays a vital role in its long-term success. While security and aesthetics are paramount, the often-underestimated attributes of easy-maintenance surfaces and exceptionally durable hardware systems are fundamental to realizing the door's full potential lifespan and value. A self-cleaning finish combats the relentless assault of dirt and weather, preserving appearance with minimal intervention. Robust hardware withstands the physical demands of daily operation, ensuring reliable function and security year after year. Together, they form the bedrock of a Building Entrance Door that delivers consistent performance, reduces ownership costs, and maintains its critical role as a dignified, functional, and enduring gateway to the building within. When evaluating options, careful consideration of these specific features provides a clear indicator of a Building Entrance Door built not just for today, but for decades of reliable service.

English

English русский

русский Español

Español عربى

عربى